Can You Taste the Difference Between Conduction and Convection?

Guest Essay by Sergio Trujillo

Desnudo Coffee - Austin, Texas

Roasted on an SRM15

The question of conduction versus convection in coffee roasting comes up often, but it is rarely explored through long-term, hands-on experience across multiple roasting platforms. This essay was written by Sergio Trujillo of Desnudo Coffee, who has roasted commercially on drum, hybrid, and fluid-bed systems before committing fully to the Sivetz SRM15. We are sharing this piece with permission because it reflects the kind of thoughtful experimentation, data-driven learning, and practical curiosity that advances roasting as a craft.

This article was originally published on the Desnudo Coffee website and is shared here with permission.

Read the original article at desnudo.coffee

Friends, Roasters, Experimenters…

Have you ever found yourself scrolling through Instagram and suddenly finding the right way to answer a question you’ve been carrying around for years?

That happened to me recently while watching an Instagram story from Christopher Feran, a dear friend and, in my opinion, one of the most knowledgeable coffee professionals out there.

The question I’ve been asking myself for a long time is a simple one:

Can you actually taste the difference between coffee roasted on a conduction roaster versus a convection roaster?

Where the Question Started

This question didn’t come from theory; it came from repetition.

Desnudo started on a small 1 kg (2.2 lb) drum roaster. Through more than 10,000 roasts, we began to understand heat, timing, and how small changes affect flavor.

From there, we moved to a 5 kg Diedrich drum roaster, still conduction-dominant, but with more thermal mass and consistency. As demand grew, we rented time at a local co-op roasting on a Loring 35 kg, our first experience with a roaster that leaned far more into convection than conduction.

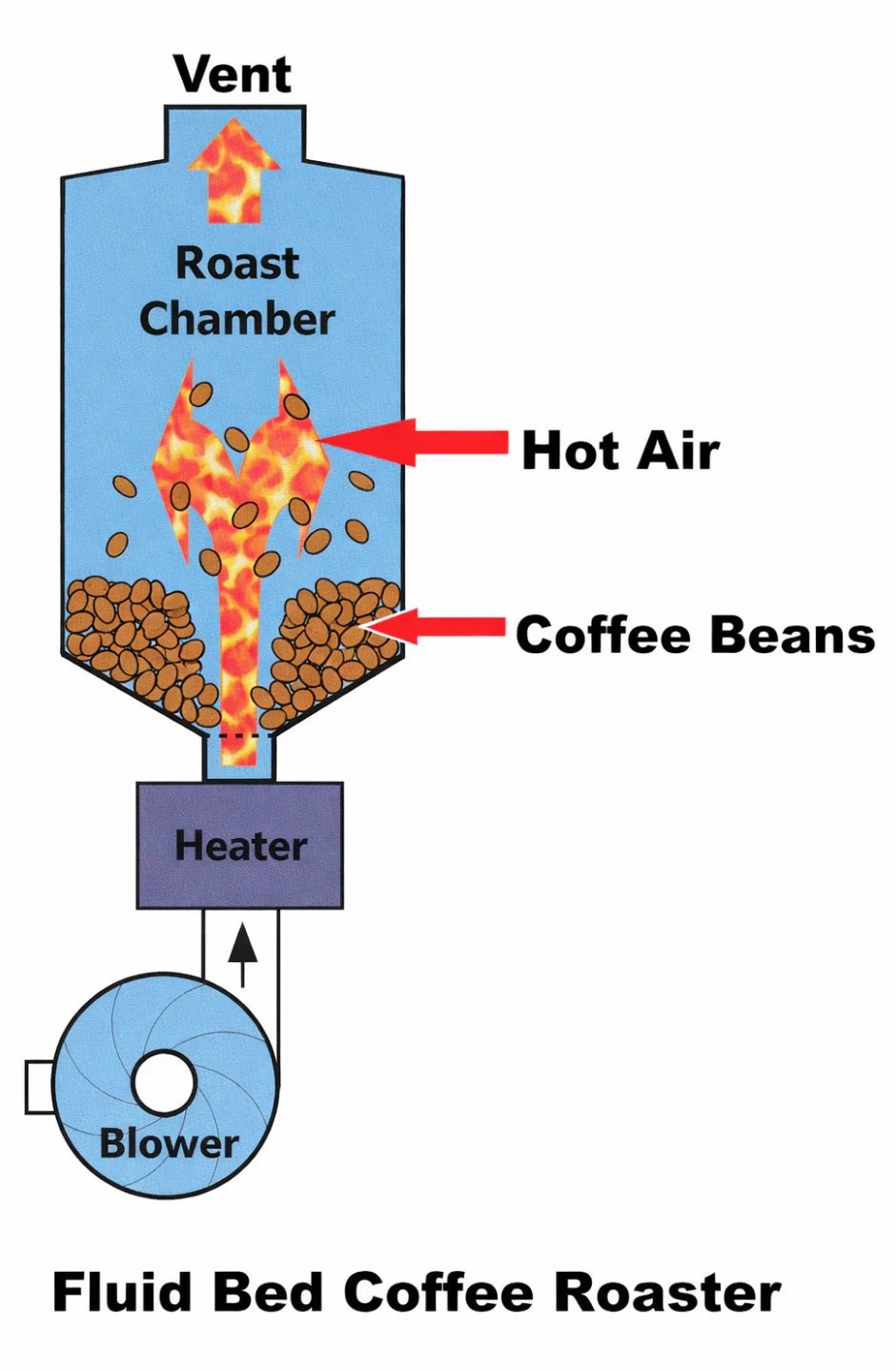

Finally, today, we roast on a Sivetz SRM15, a fluid-bed, fully convection-driven roaster.

Same goal. Same roasting philosophy of light to medium profiles. Very different machines.

Yet for a long time, I wasn’t convinced I could clearly identify a unique “machine flavor” in the cup.

When the Difference Became Noticeable

The first time the answer started to feel like a yes was when I was roasting the coffees on both the Diedrich and the Loring at the same time.

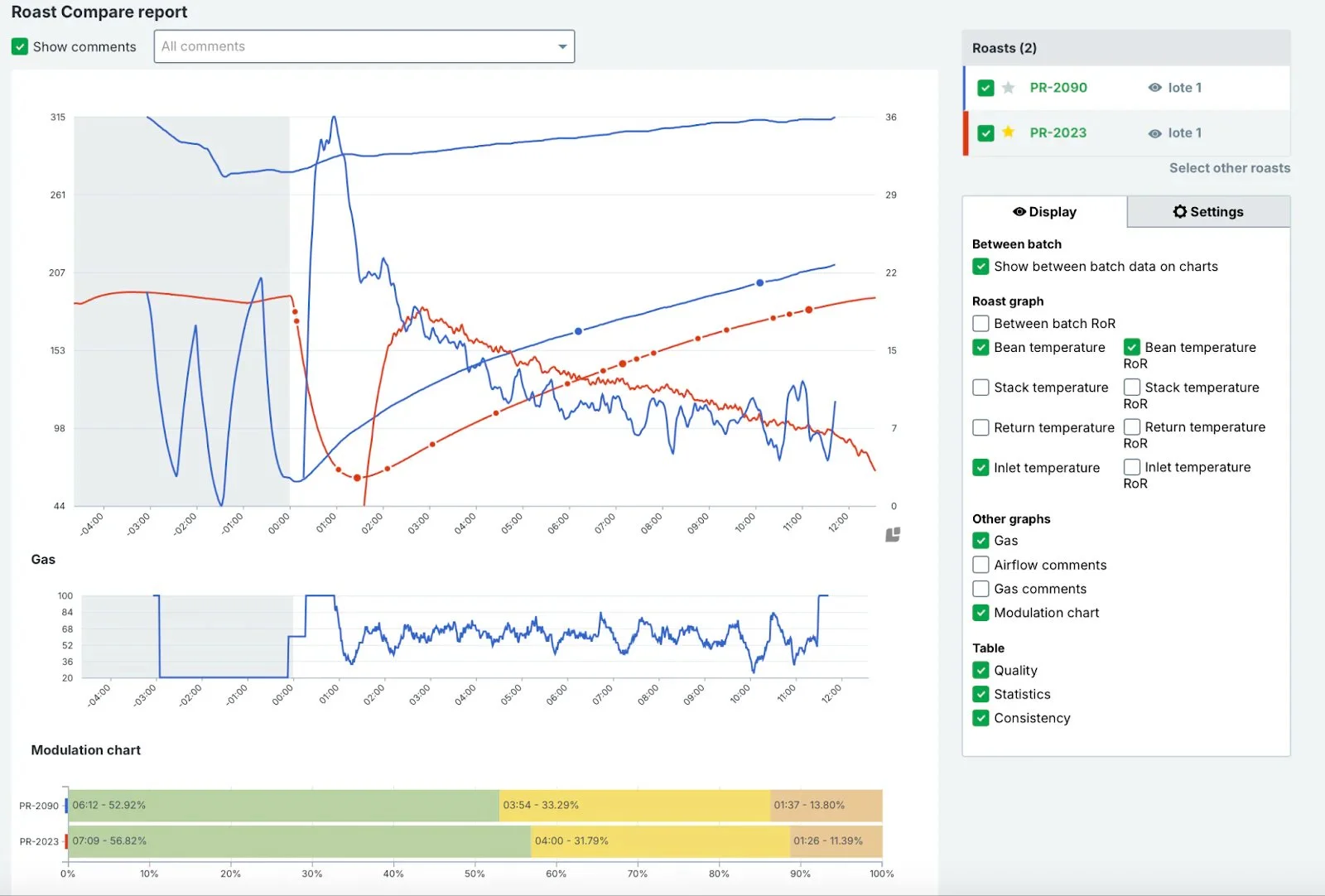

Charts and roast data courtesy of Desnudo Coffee. Shared with permission.

What I noticed was consistent:

The Diedrich (red profile) tended to produce more body and perceived sweetness

The Loring (blue profile) emphasized florals and acidity

Not better or worse, they were just different expressions of the same coffee.

That contrast planted the seed in my mind, but I still wasn’t satisfied with the answer because I knew deep down I needed to understand a little more about heat applications.

New era with the Sivetz (and a lot of Experiments)

When we finally moved into our own roastery and committed to roasting everything on the Sivetz SRM15, things got interesting.

I had never roasted on a fluid-bed roaster before. That meant hundreds of experiments and lots of failures. Learning how convection actually behaves when air is the primary driver of heat transfer.

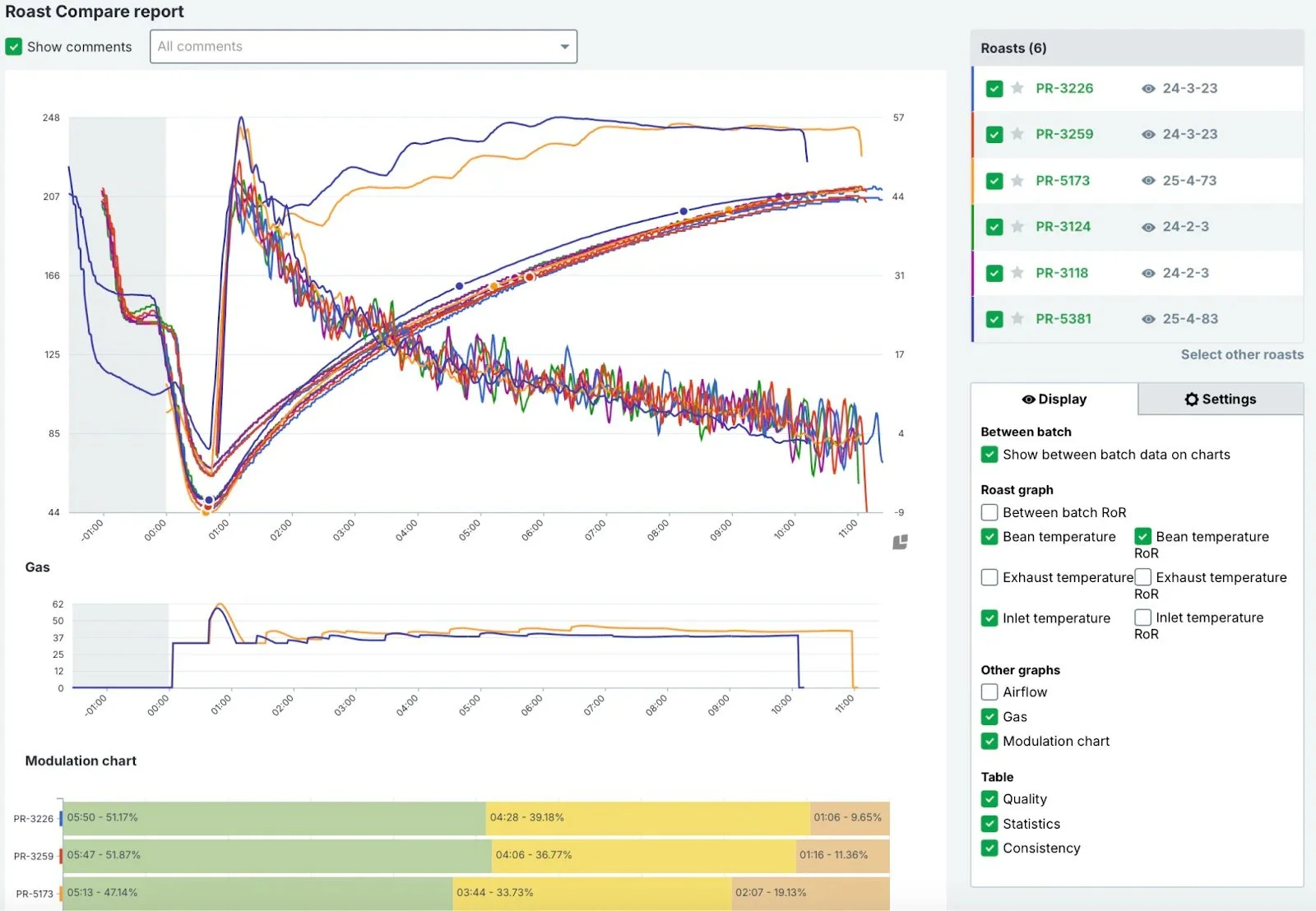

Lots of static since the early versions of Cropster did not support the Sivetz SRM15 - but this is an example of the many roasts we did.

One thing became immediately clear:

Convection roasting dramatically reduces common drum-roasting defects like scorching and tipping. Without a super-hot drum surface, heat application is gentler and more even—if the airflow is managed correctly.

A Conversation That Changed Everything

During our early Diedrich years, Daniel Mendoza helped shape how we thought about roasting through data. Yes, that Cropster software, the curves you stared at before.

At one point, he suggested adjusting fan speed to influence flavor development. I tried it, but at the time, the changes weren’t dramatic enough to notice a massive improvement.

Fast-forward to that Instagram scroll.

Christopher had just run an experiment on his Roest P3000, lowering paddle speed (similar in concept to lowering fan speed). His results surprised me:

Better body

More structure

More sweetness

Less energy input

So I asked him the geeky question I’d been holding onto.

The Geeky Part (Worth Reading)

I asked Christopher whether lowering airflow increased the conduction-to-convection ratio on the Roest P300.

His answer:

“Unlikely, based on drum temperature readings.

It’s counterintuitive. Higher air speed increases convective transfer, yes—but it also requires more energy to heat that air. The air then bypasses the coffee, leading to higher exhaust temperatures and hotter drum temps.

Lower air speed means the coffee spends more time in contact with heated air and has a greater chance to absorb that energy.”

That clicked.

In a Sivetz, airflow also controls lifting the beans, so there’s a lower limit. But I realized I hadn’t pushed that boundary far enough.

The Experiment (Again, But Better)

I lowered fan speed to the maximum point that still allowed proper fluidization, lower than I’d ever gone before.

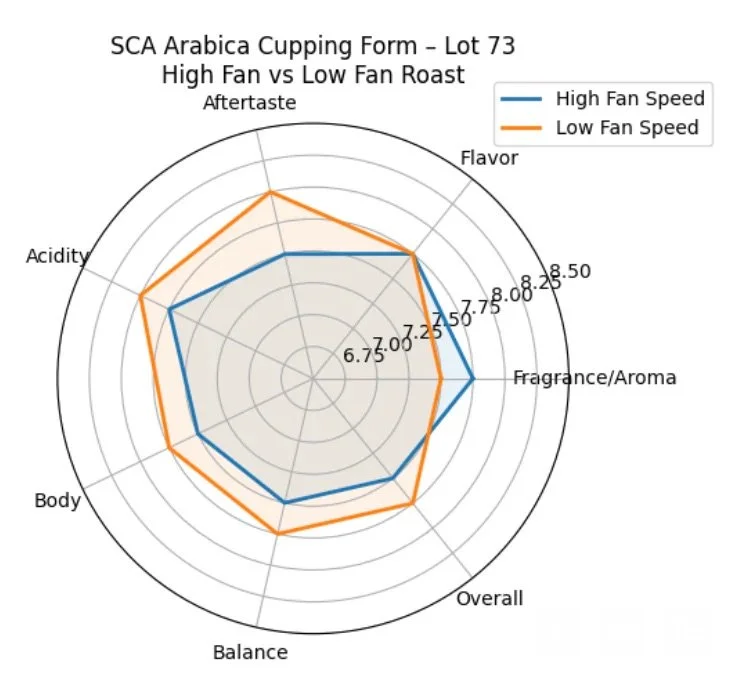

Same coffee. Two roasts. Blind cupping by a Q grader.

For this experiment, I used a Washed Castillo variety - Moisture 10.8% - Density 0.75 g/ml

Results:

Cup score improved from 83.25 → 84.5

Clear improvements in body, balance, aftertaste, and overall flavor

So… Can You Taste the Difference?

Originally, the question was:

Can you taste the difference between conduction and convection roasters?

After all of this, my answer is:

Maybe not, but that’s not the most important question.

What this experiment taught me is that you can often achieve similar flavor outcomes on very different machines if you understand:

How energy is applied

How airflow behaves

How your specific roaster actually transfers heat

It’s not conduction vs convection.

It’s how you cook the coffee.

All roads can lead to Rome!! But only if you know how to drive them.

And at the end of the day, it’s all about how you cook those beans, baby. ☕🔥

Editor’s Note:

We are sharing this essay not to argue that one roasting method is superior to another, but because it illustrates how deeply understanding heat transfer and airflow matters more than the machine itself. The SRM15 is designed to give roasters direct, repeatable control over these variables so they can explore questions like these in their own way.

Read the original post on desnudo.coffee →